H2O, H2S and O2 measurements for CCUS applications

Our complete solution will help you get a better measurement of key metrics to help you reach carbon footprints targets

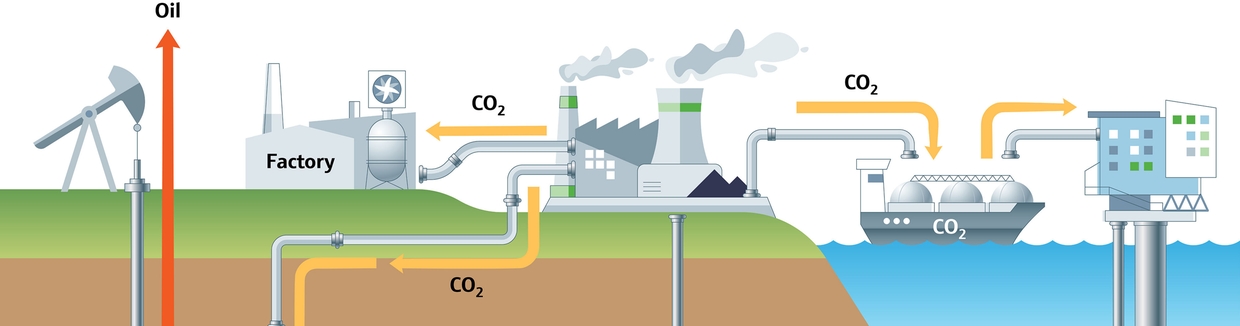

Innovative measurement technologies are required to meet defined targets set by the United Nations Convention on Climate Change – to reduce global carbon dioxide emissions by 45% by 2030 (relative to 2010 levels) and net zero by 2050. CCUS is an approach that can help to achieve these goals. CCUS involves separating CO2 from fossil power generation or industrial sources (or the atmosphere) and transporting it for reuse or permanent deep geological storage.

Benefits

Reliable H2O, H2S, and O2 analysis in CO2 processes and pipelines

High equipment availability due to the durable design and proven reliability

Improved safety, process control and quality validation at key CCUS measurement points

Accurate, real-time measurements without interferences

Compatible with ASTM test methods and global hazardous area certifications

CCUS measurement challenges

CO2 pipelines are prone to corrosion, and the presence of H2O, H2S, and O2 can speed up this corrosion process. Monitoring the levels of these impurities helps pipeline operators manage carbon removal and ensure CO2 meets quality standards. For ongoing integrity, continuous analysis is needed to detect H2O, H2S, and O2 contaminants in CO2 pipelines.

CO2 transportation and storage

Before CO2 is compressed and transported through pipelines, dehydration is necessary to prevent corrosion and ice formation. Moisture measurement ensures efficient dehydration. Reliable moisture measurement is also important during compression to prevent condensation and corrosion at compressor stations. Continuous analysis is needed to detect H2O, H2S, and O2 contaminants in CO2 pipelines for ongoing integrity.

Our solution

Endress+Hauser's TDLAS and QF analyzers are reliable for global CCUS applications, providing real-time, non-contact measurements. TDLAS analyzers accurately measure H2S in the CO2 stream during amine sweetening and perform quality validation and moisture checks. For CO2 pipeline transport, TDLAS analyzers offer real-time analysis, while QF analyzers detect O2 leaks to prevent corrosion. They outperform alternatives in speed, accuracy, stability, and maintenance.