-

Training

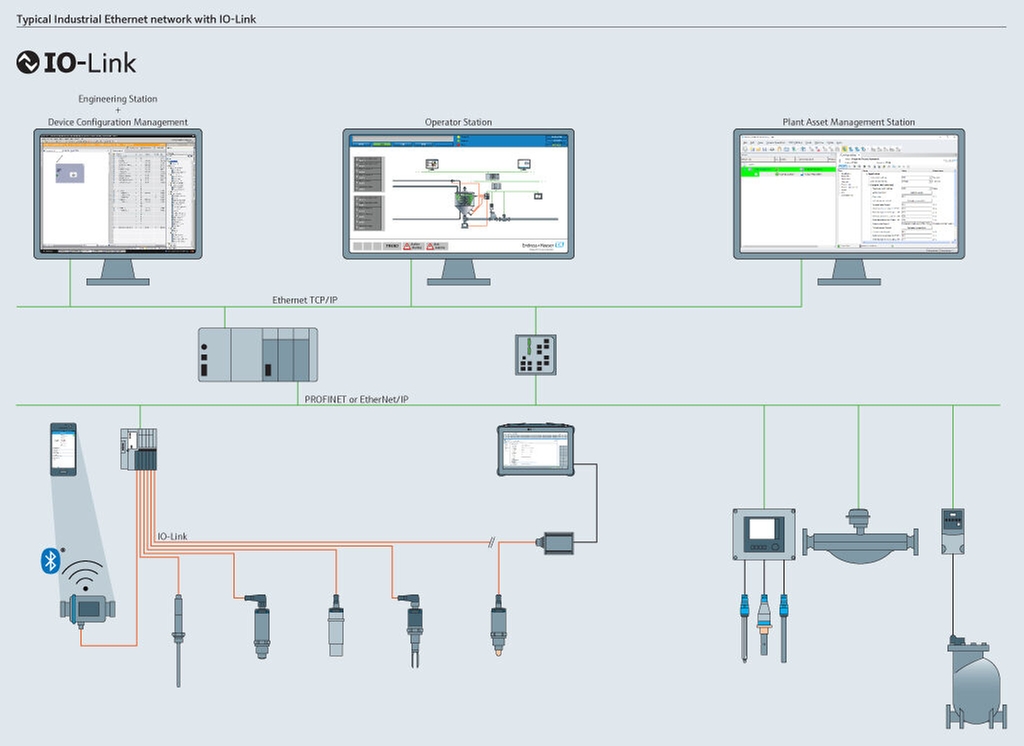

Digitalize your plant with IO-Link

Digital and cost-efficient

Digitalization of the last mile:

Smart Ethernet devices like valve islands, remote IOs, recorders, liquid analyzers or flow measurement devices are digitalized with Industrial Ethernet, e.g. PROFINET or EtherNet/IP. Basic devices also become digitally accessible with IO-Link: This makes offline parametrization, data transparency and plug-and-produce device exchange available for all devices.

Key benefits for engineers

Easy and efficient integration, e.g. by using standardized function blocks.

Ideal fit of Industrial Ethernet high-end devices accompanied by basic IO-Link devices.

Reduced variety of plugs and cabling, substitution of

DI/DO/PNP/NPN/Pulse/0…10 V / 4…20 mA signals.Reduced variety of sensors, e.g. configuration of switching points with IO-Link.

Fast commissioning and start-up, e.g. by standardized cabling and

automated parameter setting.

Key benefits for operators and maintenance personnel

Higher precision due to digital signal transmission.

Remote access and parameterization of IO-Link devices.

Availability of diagnostics with cause and remedy, including cable break detection.

Easy device exchange through automatable parameter data storage and download.

Highlights of our IO-Link devices

Accordance to IO-Link Specification V1.1. ensures best interoperability.

Additionally verified integration in our test center, e.g. Rockwell Automation, Turck and Siemens IO-Link masters.

Usage of Smart Sensor Profile Version 2 for easy engineering. I.e. provision of profile identifiers, process input/output data structure descriptions, Product ID, Firmware revision, application specific tag.

Diagnostic event data acc. to NAMUR NE 107.

Premier integration into Rockwell Automation systems.

Your benefits

Plug-and-produce device exchange:

Time-saving parameterization using the engineering system,

no need for additional software.Comprehensive access to device, diagnostics and process information.

Fast data upload/download for maintenance and service.

Simple operation:

Time-saving Endress+Hauser operating concept.

Optimal usability through guided parameterization.

User-specific menu structures and device access.

Digitalization of the last mile

Smart Ethernet devices like valve islands, remote IOs, recorders, liquid analyzers or flow measurement devices are digitalized with Industrial Ethernet, e.g. PROFINET or EtherNet/IP. Basic devices also become digitally accessible with IO-Link: This makes offline parametrization, data transparency and plug-and-produce device exchange available for all devices.

Openness with IO-Link

The IEC 61131-9 standardization of IO-Link provides a full, open,

manufacturer-independent and stable basis for your investments.All Endress+Hauser IO-Link products are tested and certified

according to IO-Link Version 1.1.The technology is proven in practice with a rapidly growing installed base of

over 9 million devices worldwide.

For detailed information: www.io-link.com

Fully digital plant

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Downloads

-

Competence Brochure IO-Link

Digitalize your plant with IO-Link. Smart Ethernet devices are digitalized with Industrial Ethernet, e.g. PROFINET or EtherNet/IP. Basic devices also become digitally accessible with IO-Link:

File size:

File name: