©Endress+Hauser

Specs at a glance

Process temperature

PA version: max. 80 °C (max. 176 °F)

Process pressure

PA pressure cylinder: max. 6 bar (87 psi)

Field of application

The Cleanfit CPA474 retractable assembly is designed for applications which require safe separation from the process and contain media that could affect stainless steel. It offers highest operating comfort: You can replace sensors and even service the assembly while the process is running. The optional electric or pneumatic control system enables automated cleaning and calibration even in difficult processes.

Cleanfit CPA474 is intended for use in tanks and pipes in:

It is suitable to be used with pressures of up to 10 bar (stainless steel cylinder) or 6 bar (PA cylinder).

Benefits

Safe and reliable separation from the process by ball valve, even under harsh conditions

Suitable for corrosive media: Only polymers (PP, PVDF, PEEK) in contact with medium

No process interruption for electrode cleaning and calibration – saves maintenance time and costs

Extended operating life of electrodes due to automatic cleaning

Flexible adaptation to all applications by great variety of materials and process connections

Success stories

Improved thickener operation at Minera Valle Central

The measurement of interface in thickeners is done manually, while the turbidity measurement is done by obtaining samples sent to the laboratory. With Endress+Hauser there is an automated solution.

Read the full story

The future of mining

Automatic cleaning, calibration, and monitoring of Memosens pH sensors with the CDC90 for efficient operations in mining applications.

Read the full story

Measurable and testable: Monitoring with Teqwave

Efficient component cleaning is an important part of the production of industrially manufactured components. Borer Chemie AG therefore relies on the concentration measurement with Teqwave F, I and T.

Read the full story

Simple products

Easy to select, install and operate

Technical excellence

Simplicity

Standard products

Reliable, robust and low-maintenance

Technical excellence

Simplicity

High-end products

Highly functional and convenient

Technical excellence

Simplicity

Specialized products

Designed for demanding applications

Technical excellence

Simplicity

FLEX selections

Technical excellence

Simplicity

Fundamental selection

Meet your basic measurement needs

Technical excellence

Simplicity

Lean selection

Handle your core processes easily

Technical excellence

Simplicity

Extended selection

Optimize your processes with innovative technologies

Technical excellence

Simplicity

Xpert selection

Master your most challenging applications

Technical excellence

Simplicity

Could also interest you

About us

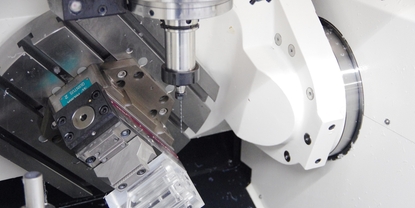

Production of assemblies

The safety and operating comfort of an analytical measuring point starts with using the right assembly. Our flexible assembly production ensures that you get the right assembly for your needs.

More information

Application

Chemical industry, wastewater, industrial water, power plants, refuse incinerators

Installation

Retractable assembly with ball valve

Characteristic

Open and closed tank, piping (min. DN80)

Design

Manual or pneumatic

Material

Seals: EPDM / FPM / perfluoroelastomer

Dimension

Immersion depth: 71 to 207 mm

Process temperature

PA version: max. 80 °C (max. 176 °F)

Process pressure

PA pressure cylinder: max. 6 bar (87 psi)

Connection

Process connection DN50, ANSI 2"

Certificates, declarations and approvals

Inspection certificate 3.1 acc. to EN 10204 on demand

Application

Chemical industry, wastewater, industrial water, power plants, refuse incinerators

Installation

Retractable holder with ball valve

Characteristic

Open and closed tank, piping (min. DN80)

Design

Manual or pneumatic

Material

Seals: EPDM / FPM / perfluoroelastomer

Dimension

Immersion depth: 71 to 207 mm (2.8 to 8.15 inch)

Process temperature

PA version: max. 80 °C (max. 176 °F)

Process pressure

PA pressure cylinder: max. 6 bar (87 psi)

Connection

Process connection DN50, ANSI 2"

Most downloaded

Technical Information Retractable Assembly Cleanfit CPA474

English version - 04/2010

Retractable process assembly with ball valve, for pH and ORP electrodes

EN

DE FR IT PL RU ZH

01/04/2010

01/02/2005

01/09/2003

01/10/2002

Language:

English

Version:

01/04/2010

File size:

1009.5 KB

File name:

TI345CEN_0410.pdf

Operating Instructions Cleanfit CPA474

English version - 04/2010

Retractable process assembly with ball valve for pH and redox sensors

EN

DE FR IT PL RU

01/04/2010

01/05/2005

01/02/2005

01/01/2004

01/09/2003

Language:

English

Version:

01/04/2010

File size:

2.2 MB

File name:

BA345CEN_0410.pdf

14 documents

Technical Information Retractable Assembly Cleanfit CPA474

Retractable process assembly with ball valve, for pH and ORP electrodes

EN

German French Italian Polish Russian Chinese

01/04/2010

01/02/2005

01/09/2003

01/10/2002

Language:

English

Version:

01/04/2010

File size:

1009.5 KB

File name:

TI345CEN_0410.pdf

Technical Information Topcal S CPC310

Fully automatic measuring, cleaning and calibration system in hazardous

EN

German French Italian Polish Russian

22/07/2015

01/07/2006

Language:

English

Version:

22/07/2015

File size:

2 MB

File name:

TI00404CEN_1315.pdf

Operating Instructions Cleanfit CPA474

Retractable process assembly with ball valve for pH and redox sensors

EN

German French Italian Polish Russian

01/04/2010

01/05/2005

01/02/2005

01/01/2004

01/09/2003

Language:

English

Version:

01/04/2010

File size:

2.2 MB

File name:

BA345CEN_0410.pdf

EA Spare parts kits for Cleanfit CPA474 process retractable assemblies

Seals, in contact with medium

Language:

English

Version:

24/02/2025

File size:

1.4 MB

File name:

EA01536CEN_0125-00.pdf

Service Manual for Retractable process assembly Cleanfit CPA474

Language:

English

Version:

20/02/2025

File size:

2.7 MB

File name:

71217190_Service_CPA474.pdf

EA Spare parts kits for Cleanfit CPA472D, CPA473 and CPA474 process retractable assemblies

Seals, not in contact with medium

Language:

English

Version:

19/02/2025

File size:

934.3 KB

File name:

EA01523CEN_0125-00.pdf

SD CleanFit Servicekits / Spare part kits

CleanFit Wechselarmaturen / Retractable assemblies

Language:

English

Version:

01/07/2003

File size:

1.6 MB

File name:

Sd096ca2.pdf

pH measurement in industrial processes

Selection and engineering guide for different industries and

Language:

English

Version:

02/12/2021

File size:

3.2 MB

File name:

CP00010CEN_1621_pH selection guide_2021.pdf

さまざまな産業およびアプリケーション向けのpH測定セレクションガイド

Language:

Japanese

Version:

08/02/2024

File size:

2.6 MB

File name:

CP00010CJA_1315_1024_pH_selection_guide.pdf

pH-Messung in Industrieprozessen

Auswahl- und Engineering-Hilfe für verschiedene Industriebranchen und

Language:

German

Version:

01/12/2021

File size:

3.3 MB

File name:

CP00010CDE_1621_pH Auswahlhilfe_2021.pdf

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

KIT CPA474 Electrode guide PP short

KIT CPA474 electrode guide PVDF short

KIT CPA474 electrode guide PEEK short

KIT CPA474 electrode guide PP long

Kit CPA474 electrode guide PVDF long

KIT CPA474 electrode guide PEEK long

KIT CPA47x:stop bolt with handle (1 pc.)

KIT CPA473/474 cylinder PA short

KIT CPA473/474 cylinder PA long

KIT CPA471 long+474 short: Cylinder SS

KIT CPA473/474 cylinder 1.4404 long

KIT CPA47x pneu.connection G1/8 AD6 10p

KIT CPA47X: Throttel check valve

Kit CPA474 rinsing chamber PP

Kit CPA474 rinsing chamber PVDF

Kit CPA474 rinsing chamber PEEK

Kit CPA474 PP press proof ,rins. chamber

Kit CPA474 PVDF pr.proof, rins. chamber

Kit CPA474 PEEK pr. proof, rins. chamber

KIT CPA474 PP-EPDM, ball valve

KIT CPA474 ball valve PP-VITON

KIT CPA474 PP-FFKM, ball valve

KIT CPA474 PVDF-EPDM, ball valve

KIT CPA474 PVDF-VITON, ball valve

KIT CPA474 PVDF-FFKM, ball valve

KIT CPA474 Actuation pneumatic complete

KIT CPA474 Actuation pneum. compl. el.

Kit CPA47: intermediate flange ball valv

Kit CPA473/474: Connection block pneumat

Pneum. proxim. switches f.retrofitting

KIT CPA473/474: Electr. proxim.switches

Outlet valve manual CPA473/474 G1/4"

Outlet valve manual CPA473/474 NPT1/4"

Outlet valve pneumatic CPA474 G1/4"

Outlet valve pneumatic CPA474 NPT1/4"

Kit CPA47x Outlet valve: O-rings Viton

Check valve CPA473/474 G1/4"

Check valve CPA473/474 NPT1/4"

KIT CPA474 rinse connectors 1/4" PVDF

KIT CPA474, rinse connectors NPT1/4"

KIT CPA471/472 shaft pneum long

KIT CPA471/472 lift tube gel hand long

KIT CPA473/474 pneum. re.pipe gel 360mm

KIT CPA473/474 manual, re.pipe gel 360mm

Texts from BDIH missing (51513001)

Texts from BDIH missing (51513002)

Kit CPA473, KCI pipe pneumatic

Kit CPA473 KCl-pipe manual

Splash protection cap for assemblies

CPA471...5 all seals w/o medium contact

Texts from BDIH missing (51511874)

O-Ring set EPDM for CPA474

Texts from BDIH missing (51511875)

Texts from BDIH missing (51511876)

O-Ring set Kalrez for CPA474

Kit CPA471 EPDM w/o scraper: sleeve

Kit CPA471 Viton w/o scraper: sleeve

Kit CPA471 Kalrez w/o scraper: sleeve

Spare parts CPA871, all materials

Kit CPA474 DN50 PVDF: Raised face

Kit CPA474 DN50 PEEK: Raised face

Kit CPA474 DN50 PP: Raised face

Kit CPA474 ANSI 2" PVDF: Raised face

Kit CPA474 ANSI 2" PEEK: Raised face

Kit CPA474 ANSI 2" PP: Raised face

Kit CPA47: Flange DN50 1.4404 (316L)

Kit CPA47: Flange ANSI 2" 1.4404 (316L)

Kit CPA472D-KCl: Exit air seal bush PVDF

Kit Sensor output interface

We value your privacy

We use cookies to enhance your browsing experience, collect statistics to optimize site functionality, and deliver tailored advertisements or content.

By selecting "Accept all", you consent to our use of cookies.cookie policy .

Customize

Accept only essential

Accept all